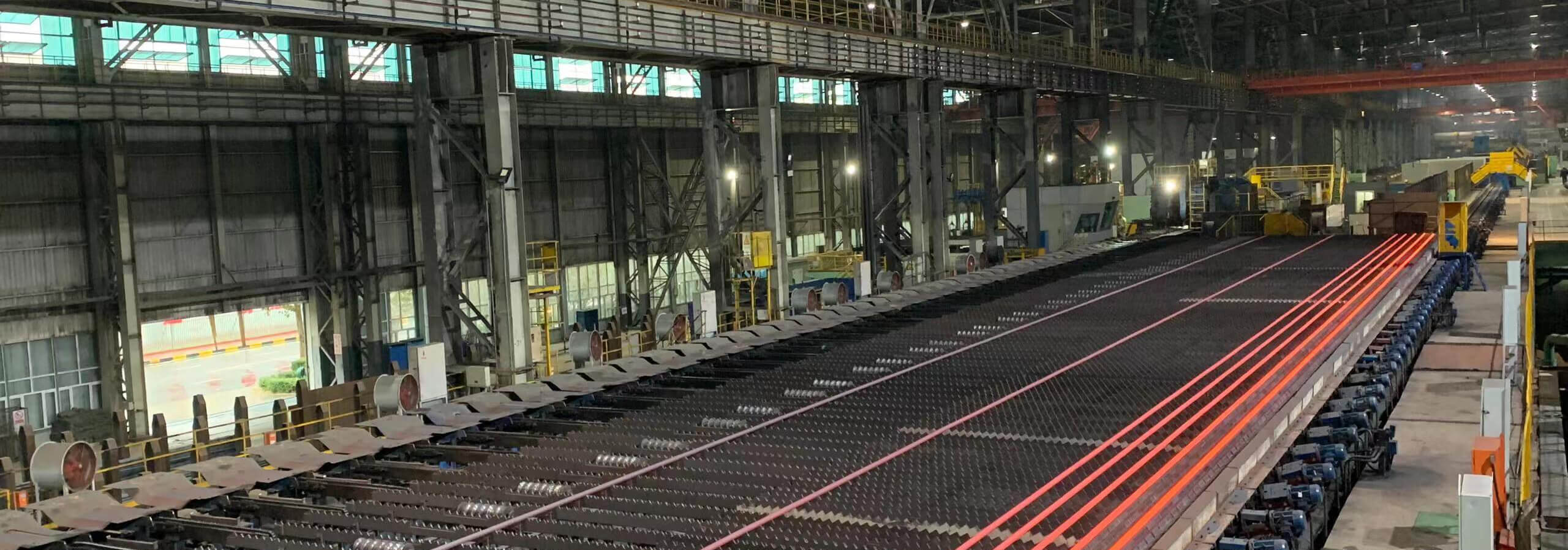

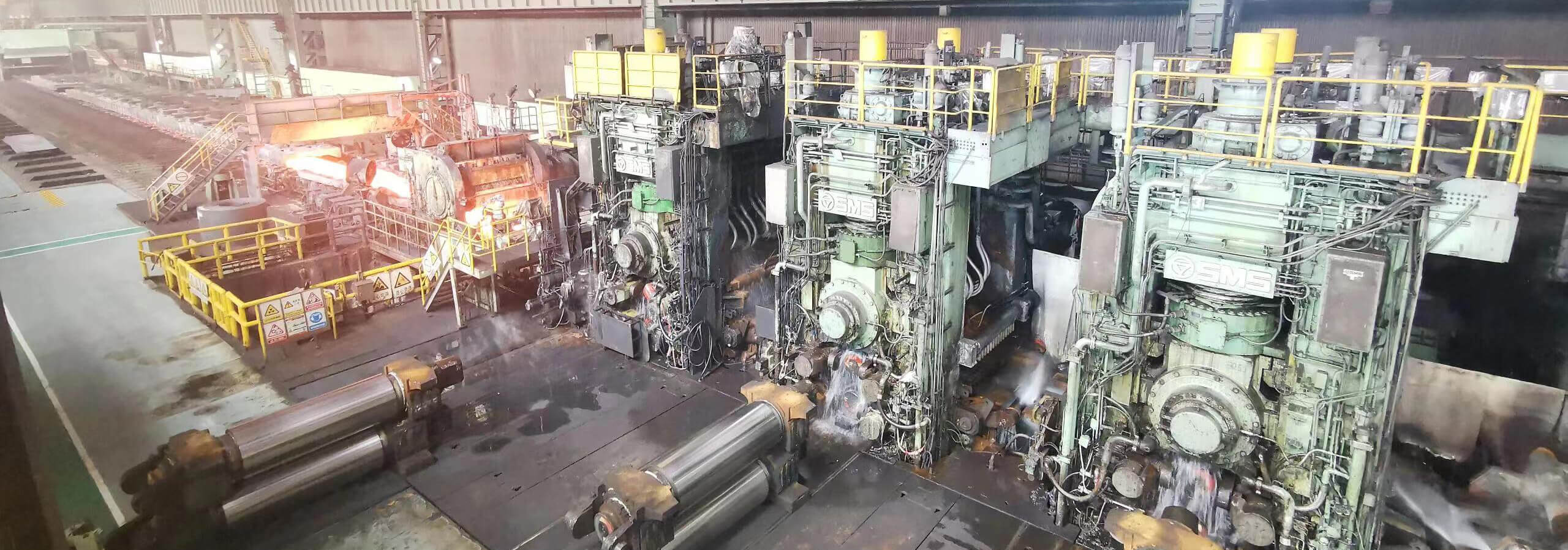

POSCO STEEL CO., LTD operates a comprehensive production system with advanced manufacturing facilities, efficiently transforming raw materials into finished products. Our Production Center is equipped with uncoiling, slitting, shearing, surface finishing, and forming processes, ensuring consistent dimensional accuracy, surface quality, and performance stability.

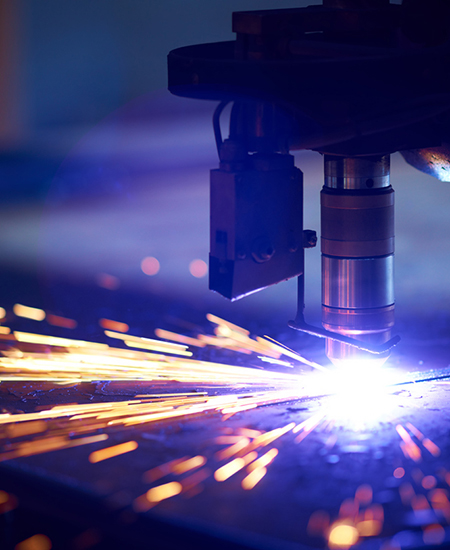

Building on this production foundation, our processing capabilities offer flexible, customized solutions. From cutting and surface finishing to bending and rolling, every step can be tailored to meet client requirements—delivering a complete, one-stop metal solution.

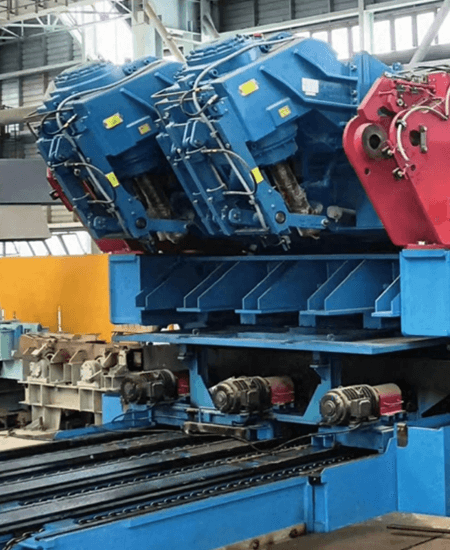

Advanced Equipment: Fully equipped with uncoiling, slitting, shearing, polishing, brushing, bending, and rolling production lines.

High-Precision Processes: Strict control over dimensional tolerances and surface flatness to ensure product quality.

Multi-Material Capability: Full processing capability for stainless steel, carbon steel, and aluminum.

Large-Scale Production: Capable of efficiently handling large orders with on-time delivery.

Quality Assurance: Rigorous inspection at every stage, from raw material to finished products.