Aluminium coil 1000 series is made from high-purity aluminum (≥99%), offering excellent corrosion resistance, electrical conductivity, and thermal conductivity, although with relatively lower strength. It is widely used in architectural decoration, food packaging, chemical equipment, and the power industry.

1000 series aluminum coils can be anodized, coated, or processed into coils, making them suitable for building facades, roofing, doors and windows, radiators, and various industrial panels.

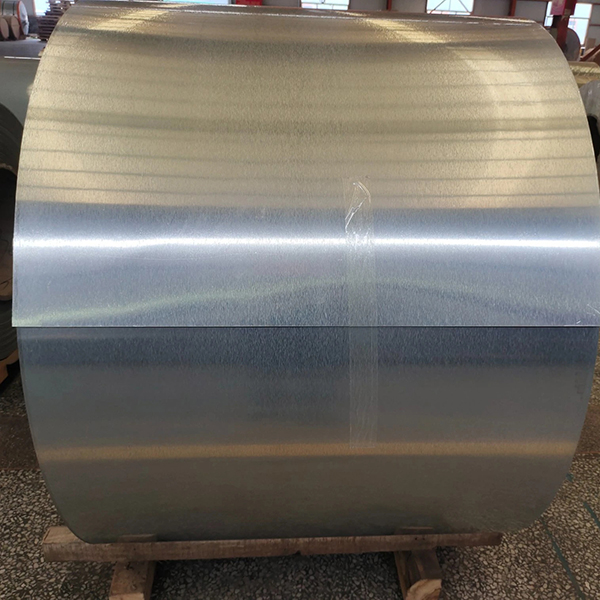

Galvanized steel coil is carbon or low-alloy steel coated with a layer of zinc through hot-dip galvanizing or electro-galvanizing processes. The zinc layer effectively prevents oxidation and corrosion, extending the service life of the steel.

Galvanized steel coils are widely used in roofing, bridges, automotive manufacturing, home appliances, piping, and light steel structures. They offer excellent corrosion resistance and cost-effectiveness, making them a common choice in engineering and industrial production.

Carbon steel hot rolled coil is produced by continuously rolling steel billets at a temperature above the recrystallization point, resulting in high strength and good ductility. Hot rolled coils have a relatively rough surface but offer a wide thickness range, making them suitable for various industrial applications.

Carbon steel hot rolled coils are widely used in construction, machinery manufacturing, automotive parts, pipe production, and shipbuilding. They serve as the basic material for making steel sheets, profiles, pipes, and structural components.

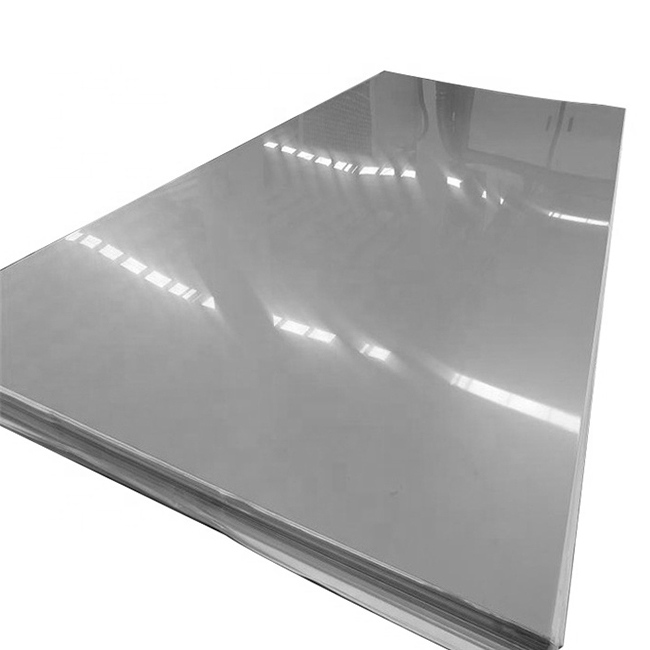

304 stainless steel sheet/plate is the most commonly used austenitic stainless steel, containing approximately 18% chromium (Cr) and 8% nickel (Ni), also known as 18/8 stainless steel. It offers excellent corrosion resistance, mechanical properties, formability, and weldability, making it widely applicable in both industrial and everyday use.

304 stainless steel is commonly used in kitchen equipment, food processing, chemical equipment, architectural decoration, water supply systems, and automotive parts, serving as a versatile stainless steel material.

Aluminium coil 6000 series is an aluminum alloy coil with magnesium and silicon as the main alloying elements, offering a good balance of strength, corrosion resistance, and machinability. It is widely used in aerospace, transportation, architectural decoration, and industrial structural components.

6000 series aluminum coils can be anodized, coated, embossed, or processed into coils, making them suitable for automotive body panels, building facades, door and window profiles, electronic equipment casings, and other high-performance structural parts.

Galvanized steel plate is carbon steel coated with a layer of zinc through hot-dip or electro-galvanizing processes to enhance corrosion resistance and prevent rust. The zinc coating effectively protects the steel from moisture and corrosive environments, extending its service life.

Galvanized steel plates offer good formability, weldability, and workability, making them widely used in construction, automotive, home appliances, bridges, storage equipment, and light industrial manufacturing.

Carbon steel cold rolled coil is produced by further rolling hot-rolled steel coils at room temperature, resulting in high thickness precision, smooth surface finish, and excellent dimensional stability. Compared with hot-rolled coils, cold-rolled coils offer higher strength, better surface quality, and superior formability.

Carbon steel cold rolled coils are widely used in home appliances, automotive, construction decoration, machinery manufacturing, and precision equipment. They are suitable for making sheets, pipes, profiles, and various stamped components.

304L stainless steel sheet/plate is a low-carbon austenitic stainless steel. With reduced carbon content compared to 304, it minimizes the risk of intergranular corrosion after welding, making it ideal for welded structures and high-purity applications.

304L stainless steel retains the excellent corrosion resistance, mechanical strength, and formability of the 304 series, making it widely used in food processing, chemical equipment, medical instruments, architectural decoration, and marine engineering.

Aluminium coil 7000 series is a high-strength aluminum alloy coil with zinc as the main alloying element, offering excellent strength, corrosion resistance, and fatigue resistance. It is commonly used in aerospace, transportation, shipbuilding, and high-strength structural components.

7000 series aluminum coils feature good machinability and surface treatment performance, suitable for anodizing, coating, or coil processing. They are widely applied in automotive manufacturing, architectural decoration, electronic equipment, and high-performance industrial components.

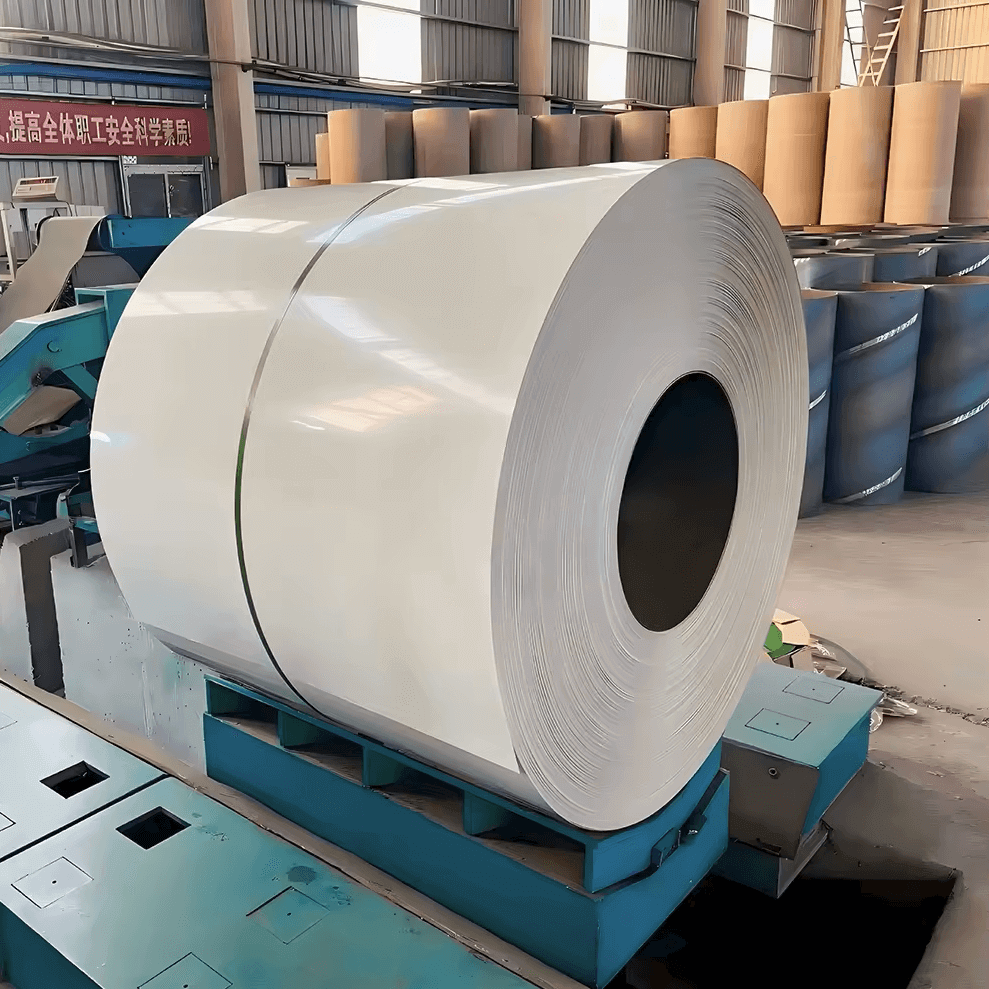

These pre-painted steel sheets are widely used in roofing, wall panels, home appliance casings, automotive parts, and light steel structures, combining decorative appeal, durability, and cost-effectiveness.

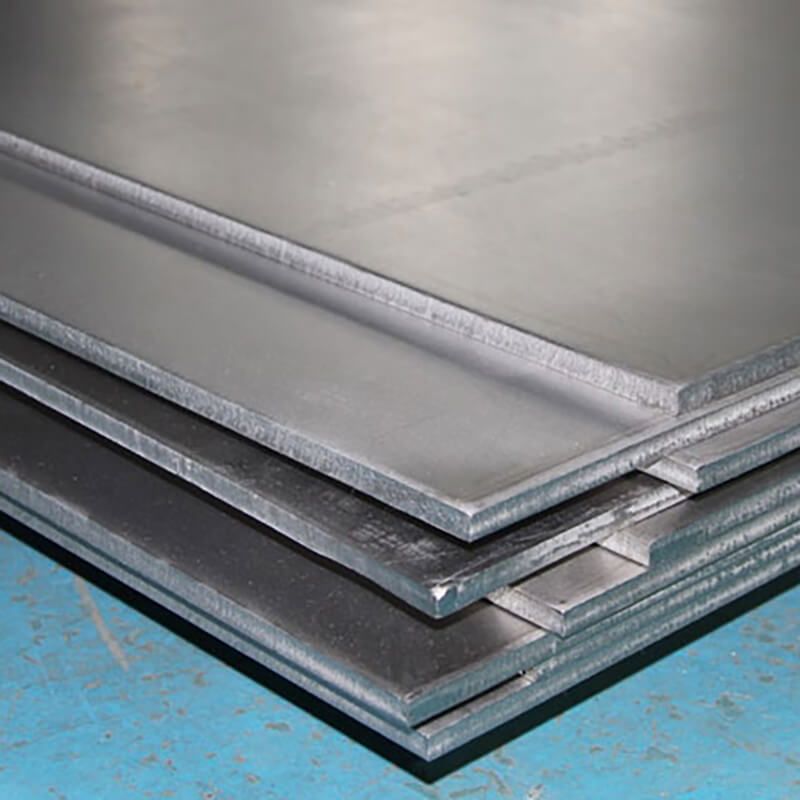

Carbon steel hot rolled plate is produced by hot rolling steel billets at a temperature above the recrystallization point, resulting in high strength and good ductility. Hot rolled plates have a relatively rough surface but offer a wide thickness range, making them suitable for various industrial applications.

Carbon steel hot rolled plates are widely used in construction, machinery manufacturing, bridges, shipbuilding, automotive, and engineering equipment. They serve as the basic material for making steel sheets, profiles, and structural components.

316 and 316L stainless steel sheets are renowned for their outstanding resistance to corrosion. With the addition of molybdenum, they outperform 304 stainless steel in resisting pitting and crevice corrosion, especially in chloride environments. They are non-magnetic in the annealed condition and retain excellent strength and toughness across both high and low temperatures.

Thanks to their hygienic properties, 316/316L stainless steel sheets are widely used in industries such as food and beverage, pharmaceuticals, chemical processing, marine equipment, and architectural decoration.

Aluminium coil 5000 series is an aluminum alloy coil with magnesium as the main alloying element, offering excellent corrosion resistance, strength, and weldability, while maintaining good formability. It is widely used in marine equipment, transportation, architectural decoration, and industrial structural components.

5000 series aluminum coils can be anodized, coated, or processed into coils, suitable for ship structures, automotive body panels, building facades, door and window profiles, and high-performance industrial panels.

Carbon steel cold rolled plate is produced by further cold rolling hot-rolled steel plates at room temperature, offering precise thickness, smooth surface, and excellent dimensional stability. Compared with hot-rolled plates, cold-rolled plates provide higher strength, better surface quality, and superior formability.

Carbon steel cold rolled plates are widely used in automotive manufacturing, home appliances, machinery, construction decoration, and precision equipment. They are suitable for stamping parts, profiles, pipes, and various precision component processing.

201 stainless steel sheet/plate is an austenitic stainless steel containing chromium and manganese, with lower nickel content, making it more cost-effective than 304 stainless steel. It offers good corrosion resistance, mechanical properties, and toughness, with a bright surface suitable for polishing.

201 stainless steel sheets are widely used in kitchen equipment, tableware, home appliance decoration, architectural decoration, and light industrial products, providing an economical and practical stainless steel option.