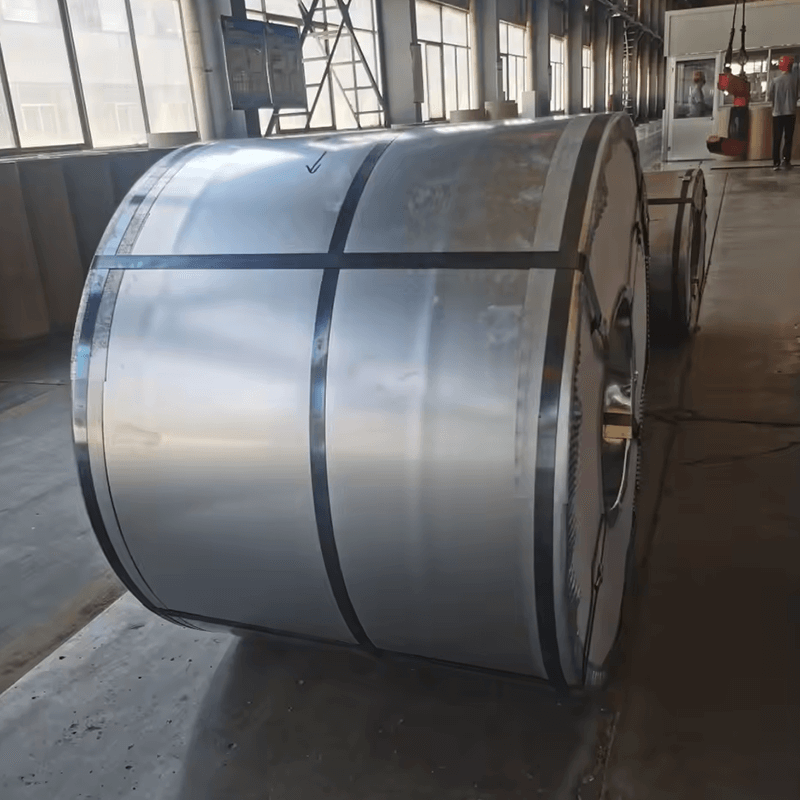

Galvanized steel plate is carbon steel coated with a layer of zinc through hot-dip or electro-galvanizing processes to enhance corrosion resistance and prevent rust. The zinc coating effectively protects the steel from moisture and corrosive environments, extending its service life.

Galvanized steel plates offer good formability, weldability, and workability, making them widely used in construction, automotive, home appliances, bridges, storage equipment, and light industrial manufacturing.

Carbon steel bar is produced from carbon steel through hot rolling or cold rolling processes, offering good mechanical properties, strength, and toughness. Depending on carbon content, it can be classified into low-carbon, medium-carbon, and high-carbon steel, each suitable for different applications and processing requirements.

Carbon steel bars are widely used in machinery parts, shafts, gears, bolts, construction components, and engineering machinery, and can be machined, welded, heat-treated, or formed into various shapes.

Carbon steel seamless pipes/tubes are manufactured from high-quality carbon steel through hot rolling or cold drawing processes. With no welded seams, they offer high strength and excellent pressure resistance. Depending on the carbon content, they can be classified as low, medium, or high carbon seamless pipes, suitable for various mechanical and engineering applications.

Carbon steel seamless pipes are widely used in oil, chemical, boiler, pressure vessels, machinery manufacturing, construction, and automotive industries. They can withstand high pressure and temperature and are suitable for transporting water, oil, gas, and other liquid media.

Carbon steel welded pipes are made by rolling carbon steel plates or strips and welding them, and can be classified into longitudinal welded pipes and spiral welded pipes depending on the welding method. They offer uniform structure, stable dimensions, and relatively low cost, making them commonly used in pipelines and construction projects.

Carbon steel welded pipes are widely used in oil, natural gas, water supply and drainage, construction, machinery manufacturing, and engineering structures. They are suitable for transporting water, oil, gas, and other liquid media.

Carbon steel cold rolled coil is produced by further rolling hot-rolled steel coils at room temperature, resulting in high thickness precision, smooth surface finish, and excellent dimensional stability. Compared with hot-rolled coils, cold-rolled coils offer higher strength, better surface quality, and superior formability.

Carbon steel cold rolled coils are widely used in home appliances, automotive, construction decoration, machinery manufacturing, and precision equipment. They are suitable for making sheets, pipes, profiles, and various stamped components.

Carbon steel hot rolled coil is produced by continuously rolling steel billets at a temperature above the recrystallization point, resulting in high strength and good ductility. Hot rolled coils have a relatively rough surface but offer a wide thickness range, making them suitable for various industrial applications.

Carbon steel hot rolled coils are widely used in construction, machinery manufacturing, automotive parts, pipe production, and shipbuilding. They serve as the basic material for making steel sheets, profiles, pipes, and structural components.

Carbon steel cold rolled plate is produced by further cold rolling hot-rolled steel plates at room temperature, offering precise thickness, smooth surface, and excellent dimensional stability. Compared with hot-rolled plates, cold-rolled plates provide higher strength, better surface quality, and superior formability.

Carbon steel cold rolled plates are widely used in automotive manufacturing, home appliances, machinery, construction decoration, and precision equipment. They are suitable for stamping parts, profiles, pipes, and various precision component processing.

Carbon steel hot rolled plate is produced by hot rolling steel billets at a temperature above the recrystallization point, resulting in high strength and good ductility. Hot rolled plates have a relatively rough surface but offer a wide thickness range, making them suitable for various industrial applications.

Carbon steel hot rolled plates are widely used in construction, machinery manufacturing, bridges, shipbuilding, automotive, and engineering equipment. They serve as the basic material for making steel sheets, profiles, and structural components.

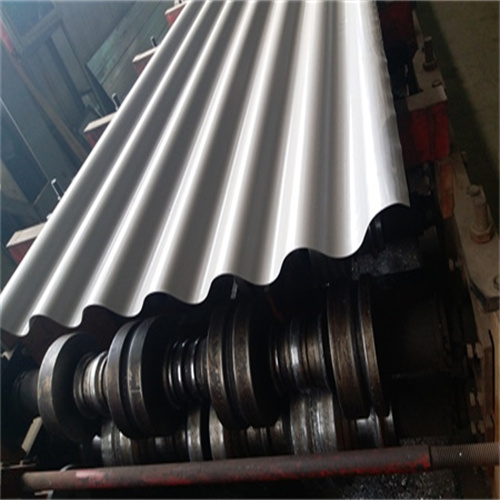

Stainless steel corrugated roofing sheet is made from high-quality stainless steel, pressed into a corrugated profile, offering durability, high strength, and aesthetic appeal. Its surface is corrosion-resistant and weather-resistant, ensuring long-term use with minimal maintenance.

Stainless steel corrugated roofing sheets are widely used in industrial buildings, warehouses, public facilities, residential roofs, and various lightweight structures. They provide waterproofing and wind resistance while enhancing the visual appearance.

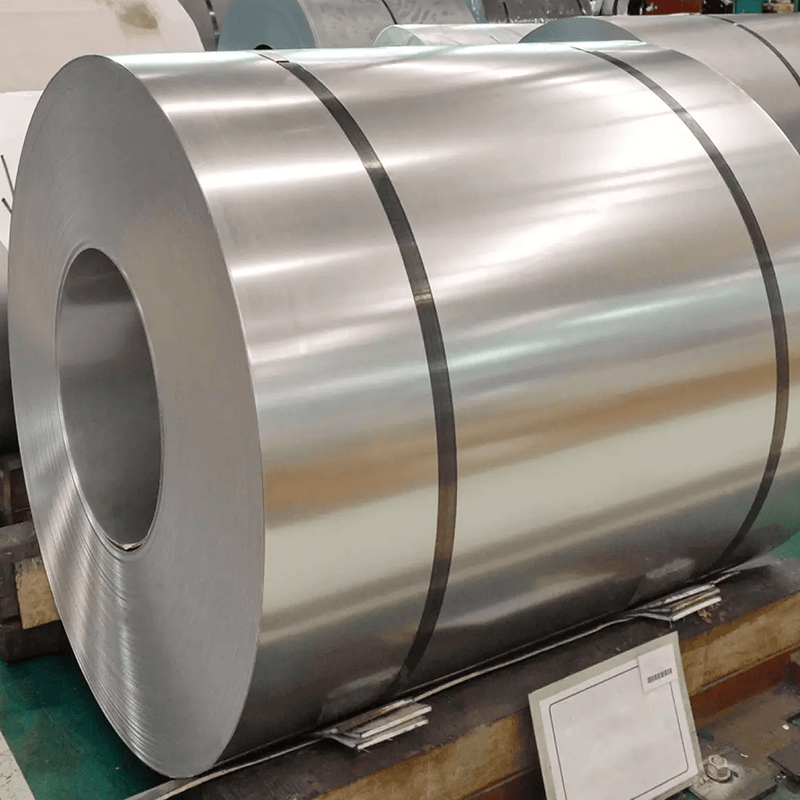

430 stainless steel coil is a ferritic stainless steel, mainly composed of chromium (Cr) with little or no nickel content, making it more cost-effective compared with austenitic grades. It offers good corrosion resistance, heat resistance, excellent formability, and polishing properties.

430 stainless steel performs particularly well in oxidizing environments and is widely used in indoor decoration, household appliances, kitchenware, automotive trim, and certain light industrial applications. Although its corrosion resistance is lower than that of 304 or 316, it is sufficient for many common uses.

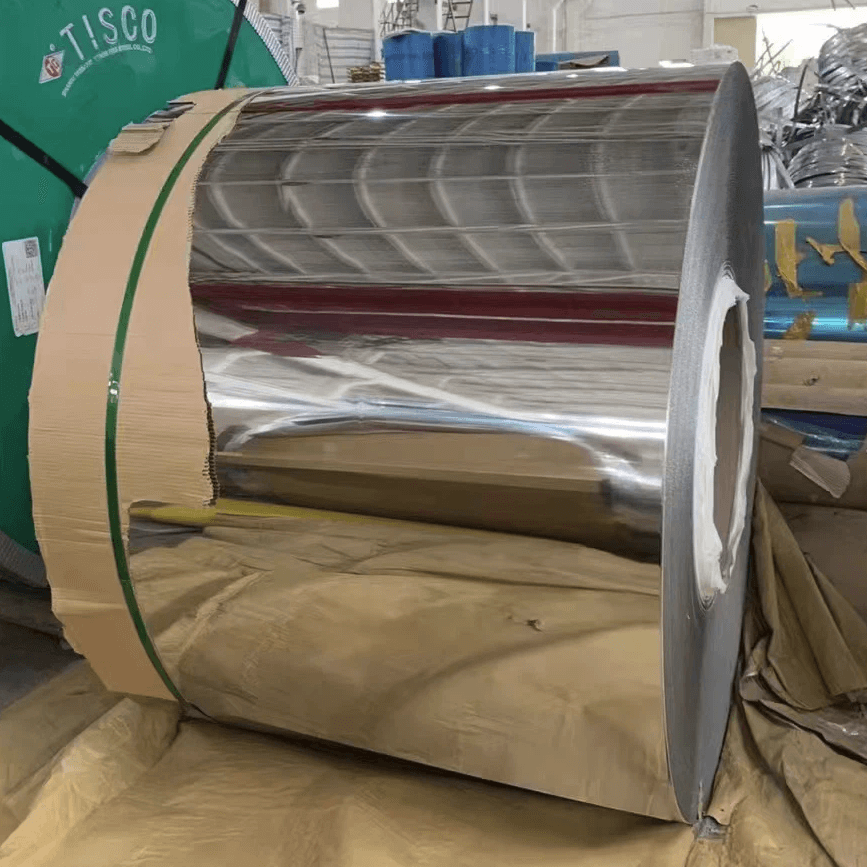

316/316L stainless steel coil is an austenitic stainless steel that contains molybdenum, providing superior corrosion resistance compared with 304, especially in chloride-containing and marine environments. The low-carbon version, 316L, minimizes the risk of intergranular corrosion after welding, making it suitable for high-purity and high-corrosion-resistance applications.

This material combines excellent strength, toughness, and formability, and is widely used in chemical equipment, food processing, medical devices, marine components, and architectural decoration.

304L stainless steel coil is the low-carbon version of 304 austenitic stainless steel. With reduced carbon content, it provides improved weldability and resistance to intergranular corrosion, making it more suitable for welded structures and pressure vessels.

At the same time, it retains the excellent corrosion resistance, mechanical strength, and formability of the 304 series, which makes it widely used in food processing, chemical equipment, medical instruments, architectural decoration, and marine applications.

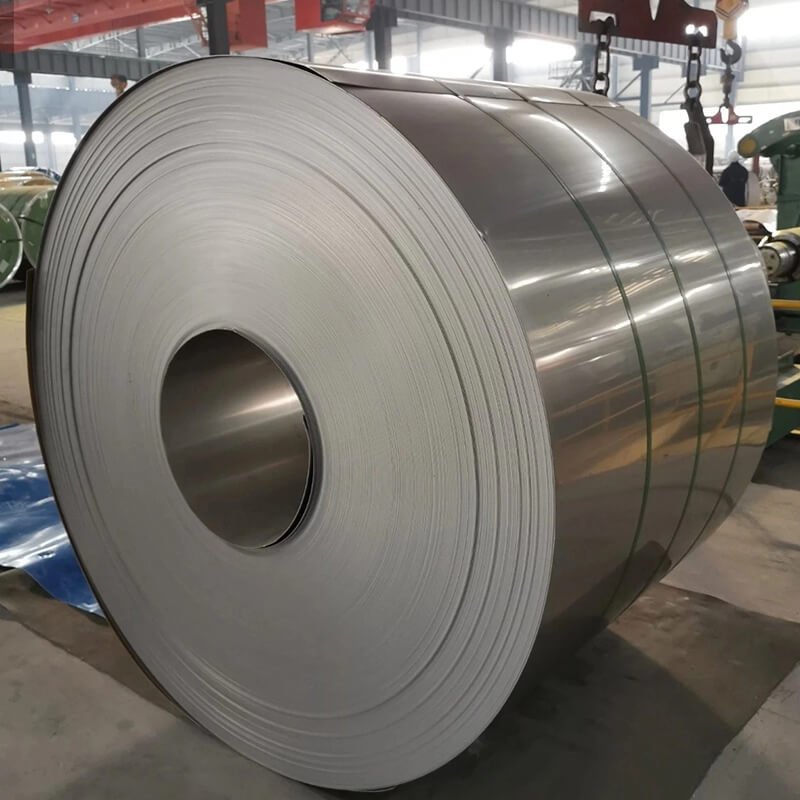

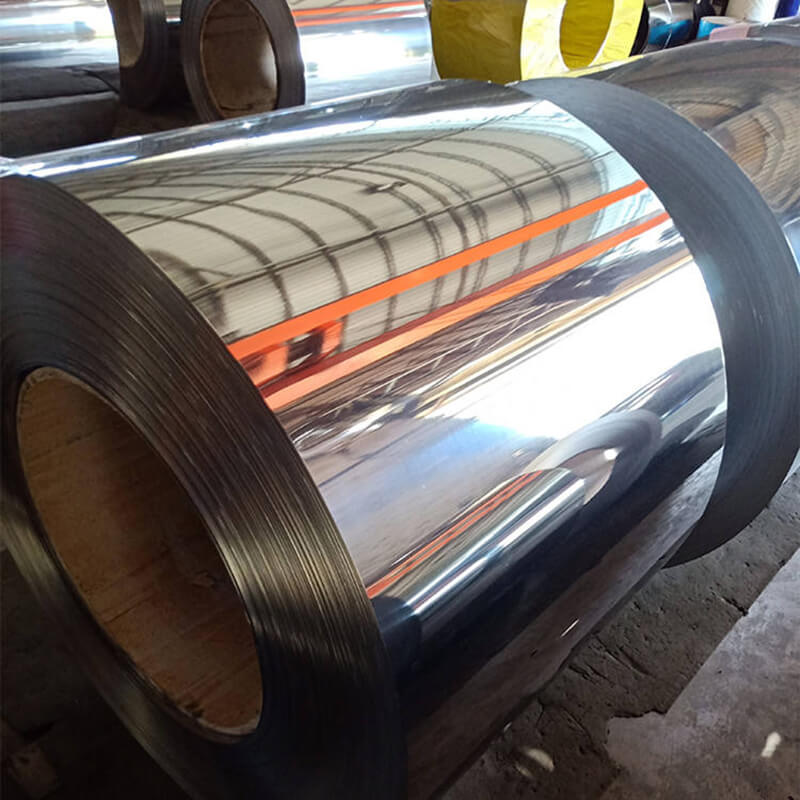

304 stainless steel coil is one of the most widely used stainless steels, belonging to the austenitic family. Containing approximately 18% chromium (Cr) and 8% nickel (Ni), it is also known as 18/8 stainless steel. 304 offers excellent corrosion resistance, good mechanical properties, and outstanding formability and weldability, making it the most versatile grade of stainless steel.

It is commonly used in kitchen equipment, food processing, medical instruments, chemical equipment, architectural decoration, water supply systems, and automotive parts.

202 stainless steel coil is an austenitic Cr-Mn-Ni stainless steel with lower nickel content, making it a more cost-effective alternative to 304. It provides good corrosion resistance and mechanical strength, along with excellent toughness and formability. Although its corrosion resistance is not as strong as 304 in harsh environments, it is sufficient for many everyday applications.

It is widely used in kitchenware, tableware, household appliances, architectural decoration, and light industrial products, making it a practical and economical stainless steel grade.

201 stainless steel coil is an austenitic Cr-Mn-Ni stainless steel with lower nickel content and higher manganese content, which reduces cost while maintaining reasonable strength and corrosion resistance. It features good surface gloss, polishability, wear resistance, and mechanical strength.

Although its corrosion resistance is not as high as 304 or 316 in harsh environments, 201 stainless steel performs well in general atmospheric conditions and decorative applications. It is widely used in kitchen equipment, tableware, household appliances, architectural decoration, and light industrial products, making it a cost-effective stainless steel option.