304 stainless steel sheet/plate is the most commonly used austenitic stainless steel, containing approximately 18% chromium (Cr) and 8% nickel (Ni), also known as 18/8 stainless steel. It offers excellent corrosion resistance, mechanical properties, formability, and weldability, making it widely applicable in both industrial and everyday use.

304 stainless steel is commonly used in kitchen equipment, food processing, chemical equipment, architectural decoration, water supply systems, and automotive parts, serving as a versatile stainless steel material.

304L stainless steel sheet/plate is a low-carbon austenitic stainless steel. With reduced carbon content compared to 304, it minimizes the risk of intergranular corrosion after welding, making it ideal for welded structures and high-purity applications.

304L stainless steel retains the excellent corrosion resistance, mechanical strength, and formability of the 304 series, making it widely used in food processing, chemical equipment, medical instruments, architectural decoration, and marine engineering.

316 and 316L stainless steel sheets are renowned for their outstanding resistance to corrosion. With the addition of molybdenum, they outperform 304 stainless steel in resisting pitting and crevice corrosion, especially in chloride environments. They are non-magnetic in the annealed condition and retain excellent strength and toughness across both high and low temperatures.

Thanks to their hygienic properties, 316/316L stainless steel sheets are widely used in industries such as food and beverage, pharmaceuticals, chemical processing, marine equipment, and architectural decoration.

201 stainless steel sheet/plate is an austenitic stainless steel containing chromium and manganese, with lower nickel content, making it more cost-effective than 304 stainless steel. It offers good corrosion resistance, mechanical properties, and toughness, with a bright surface suitable for polishing.

201 stainless steel sheets are widely used in kitchen equipment, tableware, home appliance decoration, architectural decoration, and light industrial products, providing an economical and practical stainless steel option.

430 stainless steel sheet/plate is a ferritic stainless steel with chromium as the main alloying element and little or no nickel, making it a cost-effective choice. It offers good oxidation and corrosion resistance, along with excellent formability and polishability.

430 stainless steel is widely used in interior decoration, household appliance panels, kitchenware, automotive trim, and light industrial equipment. Although its corrosion resistance is lower than that of austenitic stainless steels like 304 or 316, it is sufficient for most general applications, providing a practical and economical material option.

309S stainless steel sheet/plate is an austenitic heat-resistant stainless steel with high chromium (Cr) and nickel (Ni) content, offering excellent high-temperature oxidation resistance and corrosion resistance. Compared with 304 or 310, 309S has low carbon content, better weldability, and maintains good strength and stability at elevated temperatures.

309S stainless steel is widely used in furnace parts, heat treatment equipment, boilers, chimneys, chemical equipment, and high-temperature pipelines, where long-term high-temperature resistance and oxidation resistance are required.

310S stainless steel sheet/plate is an austenitic heat-resistant alloy with high chromium (Cr) and nickel (Ni) content, providing excellent oxidation resistance and corrosion resistance. It maintains high strength and stability even at elevated temperatures up to 1150°C, making it ideal for long-term service in high-temperature environments.

It is widely used in furnaces, heat treatment equipment, boilers, petrochemical facilities, and the power industry, and is one of the most common materials for high-temperature stainless steel applications.

2205 duplex stainless steel sheet/plate is a duplex (austenite + ferrite) stainless steel that combines the corrosion resistance of austenitic stainless steel with the high strength of ferritic stainless steel. With low nickel content and high chromium and molybdenum content, it offers excellent resistance to pitting and crevice corrosion in chloride environments, along with superior stress corrosion cracking resistance.

The 2205 duplex steel also provides high strength and good formability, making it ideal for applications in chemical processing, petrochemical, offshore platforms, shipbuilding, pulp and paper, and pressure vessels where both corrosion resistance and strength are critical.

202 stainless steel sheet/plate is an austenitic stainless steel containing chromium and manganese, with lower nickel content, making it a cost-effective alternative. It offers good corrosion resistance, mechanical properties, and toughness, along with a bright surface that is easy to polish.

202 stainless steel sheets are widely used in kitchen equipment, tableware, home appliance decoration, architectural decoration, and light industrial products, providing an economical and practical stainless steel solution.

410 stainless steel sheet/plate is a martensitic stainless steel offering good mechanical properties and moderate corrosion resistance. Heat treatment (quenching and tempering) can significantly enhance its hardness and wear resistance.

410 stainless steel is widely used in knives, cutlery, valves, bearings, pump components, mechanical parts, and wear-resistant tools. While its corrosion resistance is lower than austenitic stainless steels such as 304 or 316, it is sufficient for most applications in dry or low-corrosion environments.

420 stainless steel sheet/plate is a martensitic stainless steel known for its high hardness and excellent wear resistance. Through heat treatment (quenching and tempering), it can achieve higher strength and toughness while maintaining moderate corrosion resistance.

420 stainless steel is widely used for knives, scissors, surgical instruments, mechanical components, and wear-resistant tools and equipment. Although its corrosion resistance is lower than that of austenitic stainless steels like 304 or 316, it performs well in dry or low-corrosion environments.

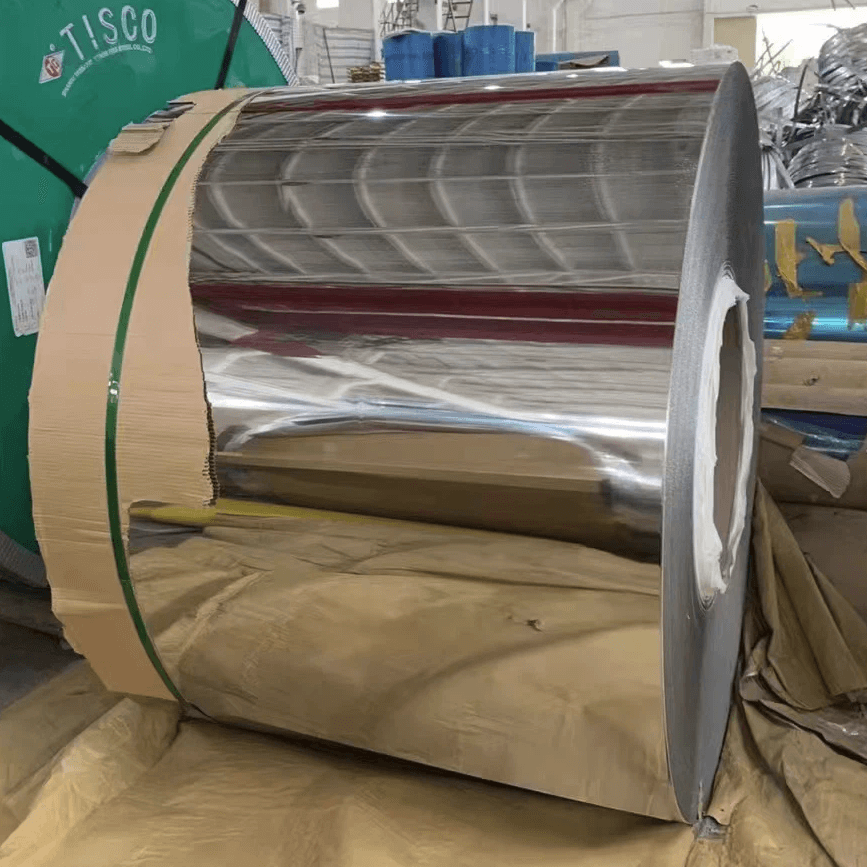

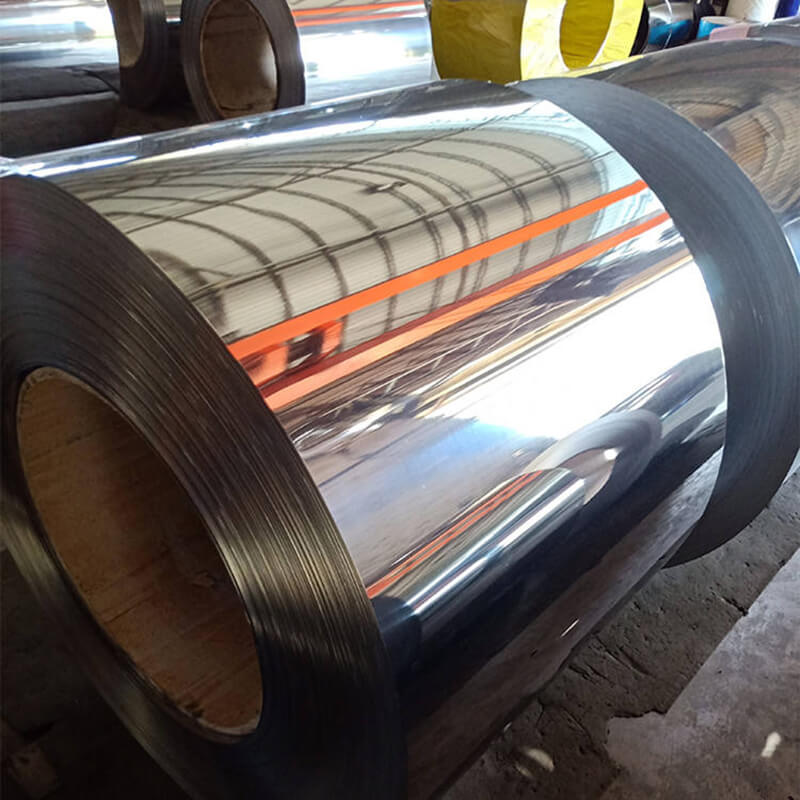

304 stainless steel coil is one of the most widely used stainless steels, belonging to the austenitic family. Containing approximately 18% chromium (Cr) and 8% nickel (Ni), it is also known as 18/8 stainless steel. 304 offers excellent corrosion resistance, good mechanical properties, and outstanding formability and weldability, making it the most versatile grade of stainless steel.

It is commonly used in kitchen equipment, food processing, medical instruments, chemical equipment, architectural decoration, water supply systems, and automotive parts.

304L stainless steel coil is the low-carbon version of 304 austenitic stainless steel. With reduced carbon content, it provides improved weldability and resistance to intergranular corrosion, making it more suitable for welded structures and pressure vessels.

At the same time, it retains the excellent corrosion resistance, mechanical strength, and formability of the 304 series, which makes it widely used in food processing, chemical equipment, medical instruments, architectural decoration, and marine applications.

316/316L stainless steel coil is an austenitic stainless steel that contains molybdenum, providing superior corrosion resistance compared with 304, especially in chloride-containing and marine environments. The low-carbon version, 316L, minimizes the risk of intergranular corrosion after welding, making it suitable for high-purity and high-corrosion-resistance applications.

This material combines excellent strength, toughness, and formability, and is widely used in chemical equipment, food processing, medical devices, marine components, and architectural decoration.

201 stainless steel coil is an austenitic Cr-Mn-Ni stainless steel with lower nickel content and higher manganese content, which reduces cost while maintaining reasonable strength and corrosion resistance. It features good surface gloss, polishability, wear resistance, and mechanical strength.

Although its corrosion resistance is not as high as 304 or 316 in harsh environments, 201 stainless steel performs well in general atmospheric conditions and decorative applications. It is widely used in kitchen equipment, tableware, household appliances, architectural decoration, and light industrial products, making it a cost-effective stainless steel option.