At POSCO STEEL CO., LTD, quality is our top priority. From raw materials and production processes to final product delivery, we implement a strict quality management system to ensure that every product meets international standards in dimensions, surface quality, and performance. With scientific inspection methods and advanced equipment, we provide clients with reliable and fully traceable high-quality products.

Comprehensive Inspection: Covering raw materials, production process, and final delivery

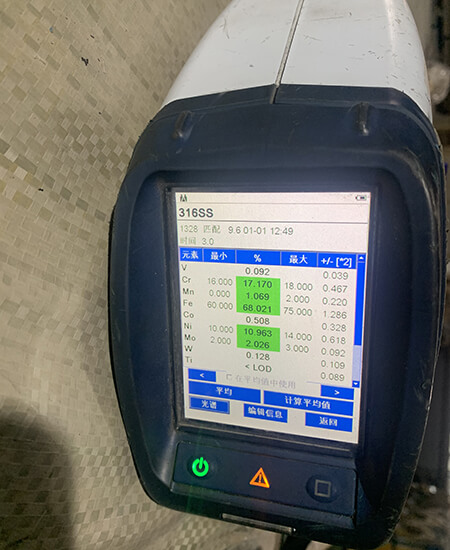

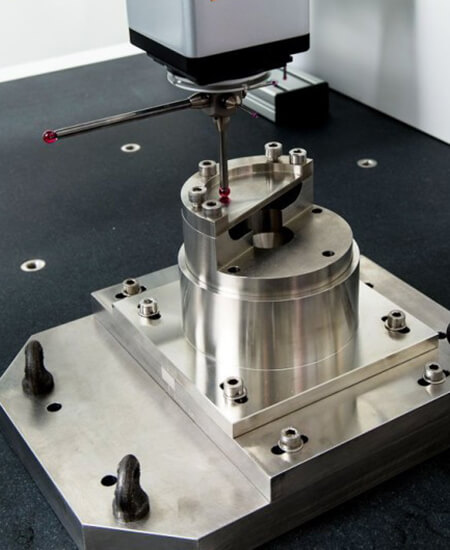

Advanced Equipment: CMM, surface analyzers, tensile testers, thickness gauges, and more

Standardized Management: Strict adherence to ISO, ASTM, EN and other international standards

High Precision Guarantee: Ensuring consistent specifications and reliable performance for every batch

Fast Response: Traceable inspection records allow quick issue resolution

To further ensure product reliability and build customer confidence, POSCO STEEL CO., LTD fully supports third-party inspection and testing. Our clients can engage independent testing agencies to verify the quality of raw materials, in-process products, and finished steel items. We provide complete documentation, including material certificates, inspection reports, and measurement records, facilitating transparent verification at every stage.

Whether it is dimensional accuracy, mechanical performance, surface quality, or coating thickness, all inspection results are traceable and reproducible. By collaborating with trusted third-party laboratories, we guarantee impartial evaluation and reinforce the credibility of our quality management system. This additional layer of assurance ensures that our customers receive products that meet both contractual requirements and international standards, providing peace of mind and confidence in every order.