Carbon Steel Cold Rolled Coil

Carbon steel cold rolled coil is produced by further rolling hot-rolled steel coils at room temperature, resulting in high thickness precision, smooth surface finish, and excellent dimensional stability. Compared with hot-rolled coils, cold-rolled coils offer higher strength, better surface quality, and superior formability.

Carbon steel cold rolled coils are widely used in home appliances, automotive, construction decoration, machinery manufacturing, and precision equipment. They are suitable for making sheets, pipes, profiles, and various stamped components.

Key Advantages:

High thickness precision and smooth surface

High strength and good ductility

Excellent formability, suitable for stamping and forming

Widely applied in appliances, automotive, construction, and machinery industries

.

Product Specification and Steel Grade (For Reference)

Application | JIS | ASTM | SAE |

Commercial Quality | G3141 SPCC | A1008 CS Type A, B, C | 1008~1012 CQ |

Drawing Quality | G3141 SPCD | A1008 DS Type A, B | 1006~1008 DQ |

Deep Drawing Quality | G3141 SPCE (N) | A1008 DDS | 1006 DDQ |

Available Size

Carbon Steel Cold Rolled sheet | ||

Thickness (mm) | Width (mm) | |

Sheet | 0.30~0.34 | 850~1100 |

0.35~0.39 | 850~1219 | |

0.40~0.49 | 850~1400 | |

0.50~0.59 | 850~1525 | |

0.60~0.69 | 850~1575 | |

0.70~2.00 | 850~1650 | |

2.01~3.20 | 850~1260 | |

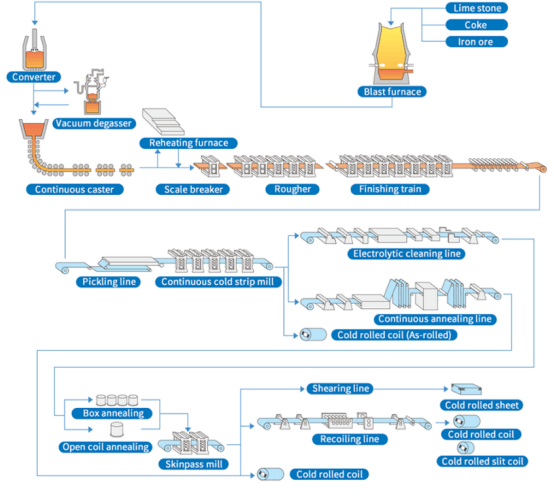

Manufacturing process

Application

Carbon steel cold-rolled steel is produced by a highly adaptable manufacturing process and is widely used in washing machines, refrigerators, electrical appliances, automobiles, and steel office equipment.By varying the content of carbon steel, different qualities of steel can be produced.In general, the higher the carbon content in steel, the more brittle, the harder, and the less tough the steel is.