Galvanized Steel Coil

Galvanized steel coil is carbon or low-alloy steel coated with a layer of zinc through hot-dip galvanizing or electro-galvanizing processes. The zinc layer effectively prevents oxidation and corrosion, extending the service life of the steel.

Galvanized steel coils are widely used in roofing, bridges, automotive manufacturing, home appliances, piping, and light steel structures. They offer excellent corrosion resistance and cost-effectiveness, making them a common choice in engineering and industrial production.

Key Advantages:

Excellent corrosion resistance

Smooth surface, suitable for secondary processing and coating

High strength and dimensional stability

Widely applied in construction, automotive, home appliances, and light structural projects

Product Specification and Steel Grade (For Reference)

Specifications | JIS G3313 SECC | JIS G3313 SECD | JIS G3313 SECE |

Application | Commercial Quality | Drawing Quality | Deep Drawing Quality |

Usage | Furniture, Computer Case, Electronic Parts, Electrical Equipment | Automobile | Automobile |

Type of Surface Treatment | Chromate Treatment, Phosphate Treatment, Oiling | ||

Available Size | Thickness: 0.3~1.6mm | ||

Width: 850~1580mm | |||

Coating Weight: 10-30g/m (single side) | |||

Max. Coil Weight: ≦ 20 MT | |||

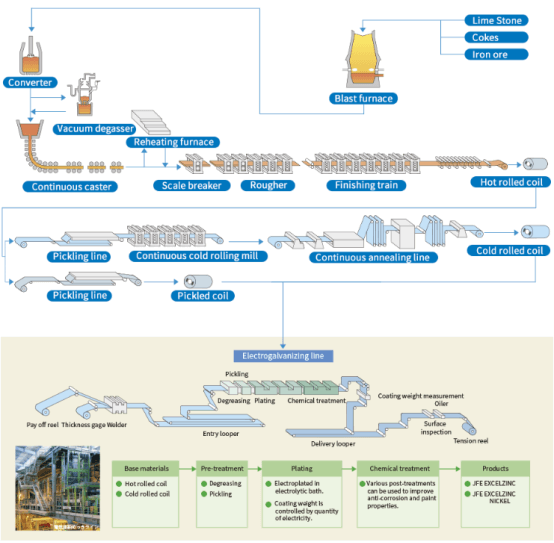

Manufacturing process

Application

Electro-galvanized steel has a good appearance and is widely used indoors.Electro-galvanized steel is an ideal material for manufacturing applications and shows excellent formability.Typical applications of electrically galvanized steel include door frames, sound-proof ceiling tiles, automobile panels, and switchboards.

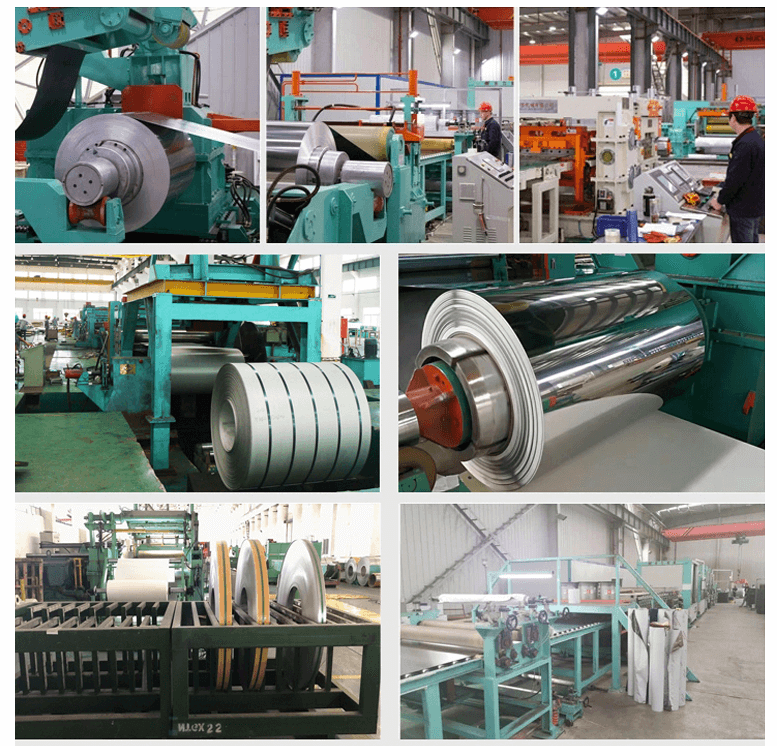

Factory Show