7000 series represents 7075, which mainly contains zinc. It also belongs to Aviation series. It is aluminum magnesium zinc copper alloy, heat treatable alloy and superhard aluminum alloy with good wear resistance. 7075 aluminum coil is stress relieved and will not deform and warp after processing All super large and super thick 7075 aluminum coil are detected by ultrasonic, which can ensure that there are no sand holes and impurities. 7075 aluminum coil has high thermal conductivity, which can shorten the forming time and improve the work efficiency. The main feature is high hardness. 7075 is a high hardness and high strength aluminum alloy, which is commonly used in the manufacture of aircraft structures.

Chemical composition of 7××× Al-Zn alloy (expressed as the highest percentage unless a range value is listed):

| Si | Fe | Cu | Mn | Mg | Cr | 锌Zn | Ti | Other elements | |

| each | A total of | ||||||||

| 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 |

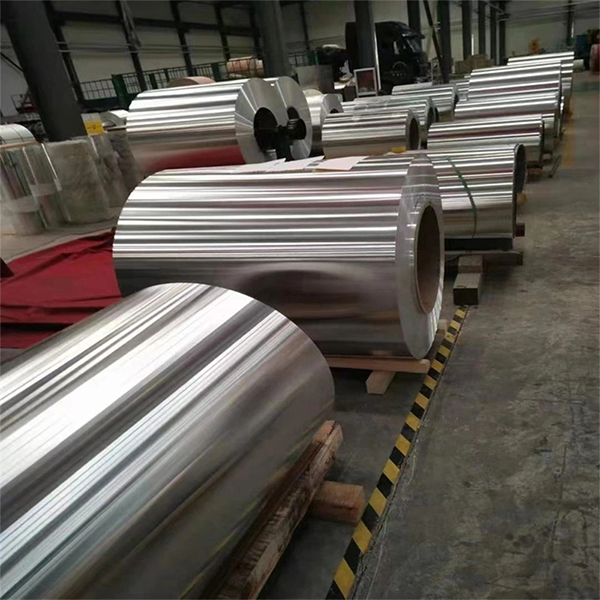

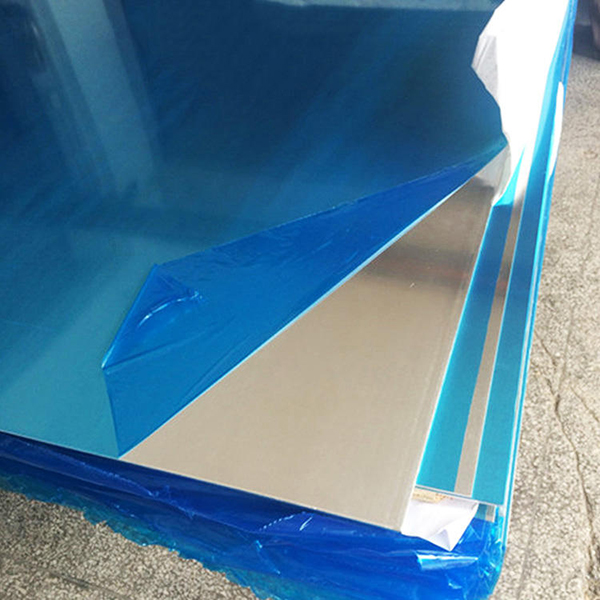

7000 Series Aluminum coil surface: shiny, polished, hair line, brush, sandblasting, mesh, embossing, etching, rolled surface treatment, no stain, no burr, pattern, printing.

7000 series aluminum coil features corrosion resistance, heat resistance, high hardness, good ductility.7000 series aluminum coil Applications: industrial, transportation, architectural modeling, automobile, medical machinery, etc.

The following is the application scenario of the 7 Series aluminum coil:

7005: Process is an extruded material used to manufacture welded structures with high strength and fracture toughness, such as trusses, rods, and containers of transportation vehicles; Large heat exchanger, to absorb welding after the solution treatment of the components; On a smaller scale, it can also be used to make sports equipment such as tennis rackets and softball bats.

7039: Commonly used in refrigerating vessels, cryogenic instruments and storage tanks, fire pressure equipment.

7049: Good corrosion resistance, commonly used for forging parts with the same static strength as a 7079-T6 alloy that requires high-stress corrosion cracking resistance, such as aircraft and missile parts.

7050: Commonly used in aircraft structure plate, extrusion, free forgings, and die forgings. The aluminum coil has good corrosion and cracking resistance, fracture toughness, and fatigue resistance.

Used for home furnishings, such as air conditioner aluminum foil and special thin strip;

7075: wide range of use, often used in manufacturing aircraft structure and other requirements of high strength, strong corrosion-resistance of high-stress structural parts, mold manufacturing;

7175: High strength structural parts for forging aircraft

7178: Parts for the manufacture of aerospace and spacecraft requiring high yield strength; Aluminized and unaluminized panels for airframes, wing frames, booms, etc.

7A04: Aircraft screws, suction force components such as girder beams, spacers, ribs, landing gear, etc.